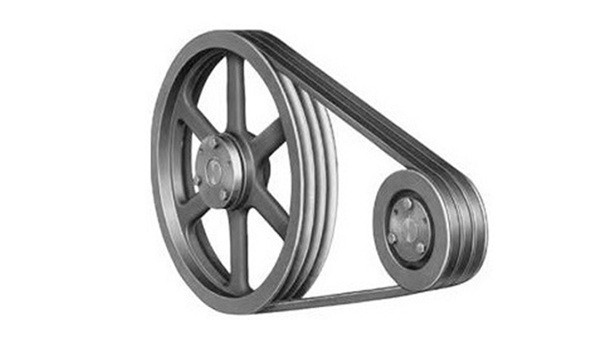

Trapezoidal-shaped belts referred to as V-belts. They are employed in the same manner as other types belts to transfer force or torque from the driving to the driven component. The system’s output more consistently produced because of its design, which makes it easier to hold onto the roller components (such as pulleys) when they are in use and reduces the chance of slippage. These parts are available in range varieties, each of which has unique qualities that make it appropriate for various applications for correas trapeciales.

1) Classical V-Belts categorised according to their sizes, which range from A to E.

Of V-Belt kinds traditional V-Belt is the most prevalent and dates back further than the others. Due to its wide application range in various industries, including agriculture, industrial machinery, ventilation, etc., this type correas trapeciales can handle loads of up to 500 horsepower. The Narrow Wedge is unquestionably more effective than the traditional V-Belt, but it also works well with heavier bearing loads and has a high tolerance for unfavourable working conditions.

2) Narrow Wedge – Defined as having dimensions between 3V and 8V

The fundamental advantage of this sort of V-Belt over the Classical type is that they have the most significant degree of force distribution and load transmission. As a result, they are more effective than the Classical type. The Narrow Wedge is well suited for high speed and is widely known for its powerful compact form. It can transmit three times the horsepower that a traditional V-Belt would in the same drive space. Narrow Wedge can handle drives from 1 horsepower to 1,000 horsepower traditional V-Belt.

3) Fractional Horsepower – Grouped according to size, which can be 2L, 3L, 4L, or 5L.

The Fractional Horsepower V-Belt operates differently from the previously stated two varieties of V-Belts since it is only intended for light loads and is frequently used as a single belt on drives have horsepower ratings of one or even lower. Domestic appliances with this kind of belt common includes refrigerators, fans, and washing machines. Even if it is perfectly fractional equine power cannot utilise on any heavy-duty industrial gear.

How Do V-Belts Function?

The primary components of a standard wrapped V-belt are as follows:

Basic rubber substance. The bulk of the V-belt made of rubber, which also serves as a shock absorber. Tensile Structures. The rubber of the V-belt embedded with tensile elements, sometimes known as “cords,” which provide it strength and the capacity to transmit power.

Covert protection. The textile cover ensures the proper grip for power transfer and shields the rubber from external impurities and wear caused by friction. Together, these parts enable wrapped V-belts to serve their original purpose is transfer torque and power between pulleys through friction.